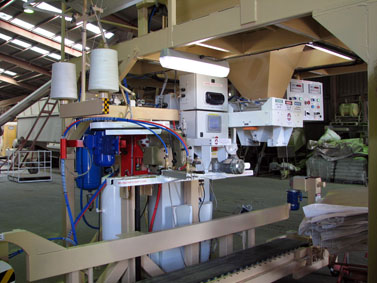

SHORT AUTOFEED SYSTEM DETAILS:

|

Manual bagging systems require a sewing machine operator and a bag placer.

We have developed a system under operational conditions in our plant with unique features that work very reliably.

Speeds of up to 12 bags a minute for Short Autofeed Systems depending on product packed.

All the equipment in our grain processing facility is of our manufacture and is running under daily production conditions - basic proved designs are constantly improved and new ideas and technologies are tested on the factory floor.

|

PROGRAMMED TOUCH SCREEN PAGES ON OUR SYSTEMS: |

Touch screen control, enabling the operator to see and operate easily a whole range

of functions not possible on conventional push button control panels.

like:

1. |

Bags per minute |

2. |

Bag counter / Batch |

3. |

Batch complete prompt. |

4. |

Weigh bag prompt. |

5. |

Oil sewing machine prompt. |

6.. |

Dual cotton break prompt |

7. |

Low air pressure prompt. |

8. |

Dust filter prompt. |

9. |

Bag hold prompt. |

10. |

Scale interlock when the sewing conveyor is stationary. |

11. |

Push button speed control changes while operational. |

12. |

Variable speed drives, fault prompting system |

13. |

Sewing head height control while operational. |

14. |

Operators guide and fault finding. |

15. |

Auto to Manual quick changeover system, with a detailed guide. |

16. |

Additional prompts can be added to the system to instruct and remind workers

regarding health and safety issues and prevent use by unauthorised personnel. |

| 17. |

Touch screen control raise and lower of sewing conveyor to suit different bag heights. |

|

Some brief information.

We have found operators in our plant really like the touch screens

.

When we quizzed them why, these are some of the replies.

Being able to see their performance while operating the machine.

Its interesting when a prompt screen comes up and has to be acknowledged before continuing.

If there's a problem a new screen appears with a written explanation.

|

|